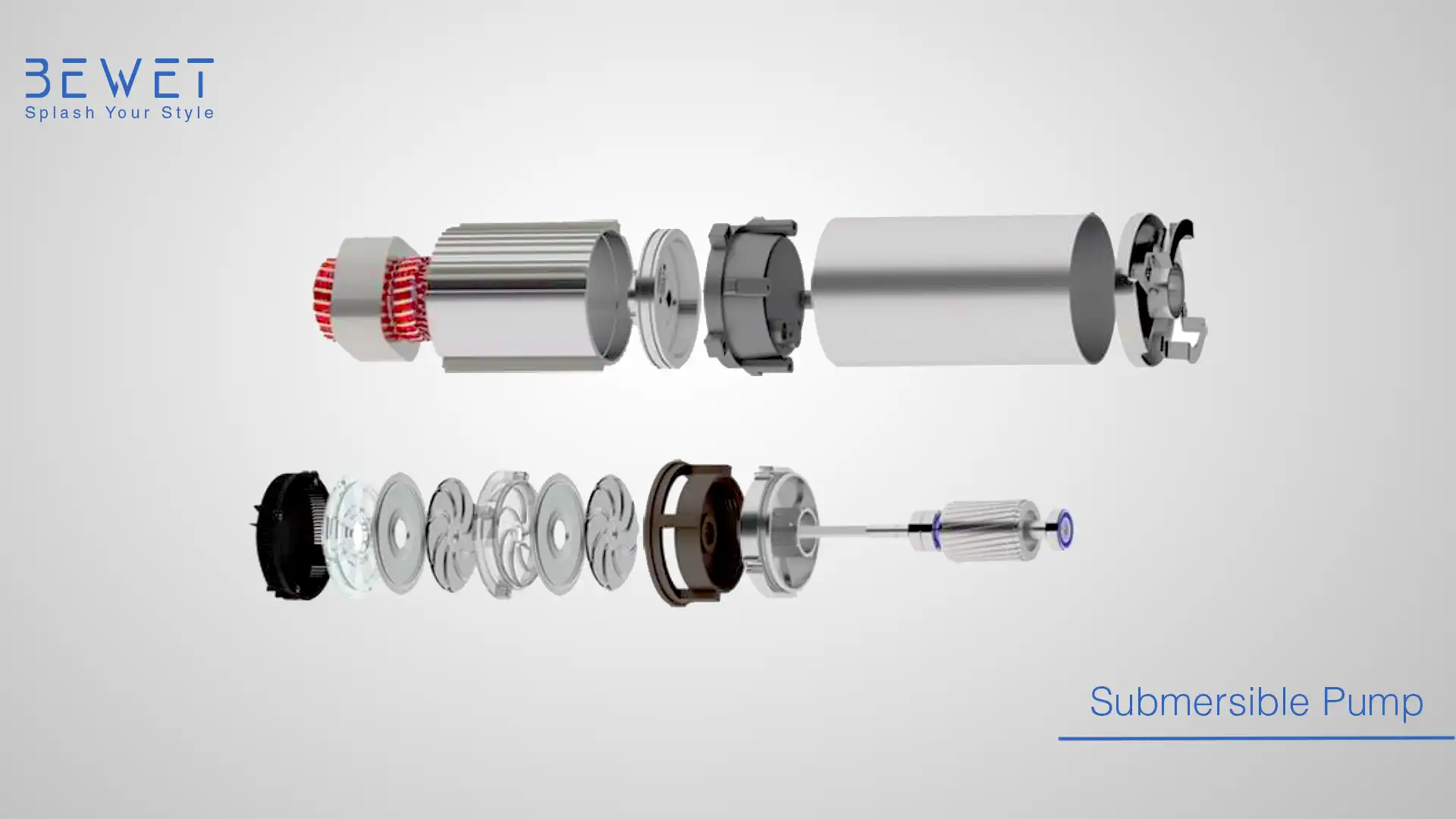

The BE WET Submersible Pump, featuring the advanced NSS models, showcases the pinnacle of engineering from BE WET, a global leader leveraging top-tier experts and cutting-edge machinery while adhering to international standards. The NSS model, designed for clean water applications, boasts a die-cast aluminum 413 motor housing and durable, transparent polycarbonate diffusers resistant to impact and corrosion. An oil-filled chamber between the pump and motor enhances mechanical seal longevity, ensuring watertight performance and easy coil separation.

Technical Specifications of NSS Submersible Pump

-

Maximum fluid temperature: 45°C

-

Motor speed: 2900 RPM

Key Features of NSS Submersible Pump

-

Designed for Clean Water: Engineered specifically for clean water applications, ensuring optimal performance.

-

Stainless Steel 304 Body: Crafted with corrosion-resistant stainless steel 304 for enhanced durability.

-

Single-Phase Two-Pole Motor: Features a reliable induction motor for consistent operation.

-

Carbon/Ceramic/NBR Mechanical Seal: Equipped with a high-quality seal for long-lasting watertight protection.

-

420 Stainless Steel Shaft: Built with a robust shaft to withstand demanding conditions.

-

304 Stainless Steel Impeller: Ensures strength and efficiency in water flow dynamics.

-

CE and ISO 9001 Certified: Meets international standards for quality and safety assurance.

-

6-Month Repair Warranty: Backed by a warranty for dependable engineering solutions.

BE WET Pump Technical Specifications Table

| Model | Inch | Height (m) | Flow Rate (L/m) | Power (W) | Amperage (A) | RPM | Weight (Kg) |

|---|---|---|---|---|---|---|---|

| NCH 22.4.1 | 1-1/4" | 22 | 185 | 750 | 5 | 2800 | 15.5 |

| NCH 35.4.2 | 1-1/4" | 35 | 185 | 1000 | 6.5 | 2800 | 17.5 |

| NCH 40.4.2 | 1-1/4" | 40 | 190 | 1100 | 8.5 | 2800 | 19.5 |

| NCH 56.4.3 | 1-1/4" | 56 | 190 | 2000 | 10.5 | 2800 | 21 |

| NCH 70.4.4 | 1-1/4" | 70 | 165 | 2200 | 12 | 2800 | 23 |

| NCH 90.4.5 | 1-1/4" | 90 | 165 | 2200 | 14 | 2800 | 24 |

| NCH 18.6.1 | 2" | 18 | 390 | 1000 | 6.5 | 2800 | 17 |

| NCH 28.6.2 | 2" | 28 | 390 | 1100 | 8.5 | 2800 | 21 |

| NCH 35.6.2 | 2" | 35 | 390 | 1100 | 10.5 | 2800 | 22 |

| NCH 45.6.3 | 2" | 45 | 390 | 2200 | 12.5 | 2800 | 23 |

| NCH 53.6.3 | 2" | 53 | 390 | 2200 | 14 | 2800 | 25 |

| NCH 63.6.4 | 2" | 63 | 390 | 2300 | 16 | 2800 | 26 |

| NCH 15.9.1 | 3" | 15 | 1000 | 2000 | 10.5 | 2800 | 21 |

| NCH 30.9.2 | 3" | 30 | 570 | 2200 | 14 | 2800 | 25 |

| NCH 45.9.3 | 3" | 45 | 570 | 2300 | 16.5 | 2800 | 27 |